Seamless Tubing as per API 5CT and various international standards with API, Semi Premium and Premium connections

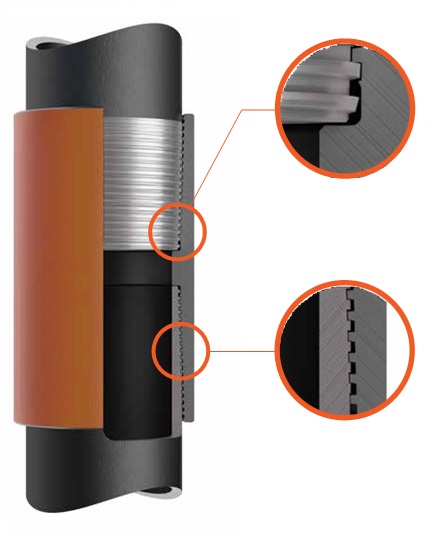

AM-BLADE

4 ½” TO 13 5/8”

- Latest Premium Connection generation, combined with the highest performance and most stringent Testing Qualification conditions.

- Patented connection tested under API RP5C5 CAL IV. This is the latest and most severe testing protocol.

- Product line qualification testing performed on broad size, weight and grade range. Connection incorporates the most advanced casing and tubing technology and has been designed for the most challenging combination of environments and well conditions.

Metal-to-Metal Seal

- Reverse “ball & socket” seal provides outstanding gas tight seal

- Engineered seal design provides flexibility to ensure seal integrity during bending

- Seal geometry provides excellent anti-galling properties

- Resistant to handing damage

Torque Shoulder

- Wedge shaped torque shoulder provides seal stability

- Large shoulder area for high compression resistance

- Ensures precise make up position control

Thread Profile

- Run out thread provides maximum pipe body area for tension and compression

- Hooked threads lock the joint together for maximum tension loads and preventing jump out

- Steep stab flank angle and torque shoulder provide maximum compression and bending resistance

- Thread form design provides excellent anti-galling properties

Other features

- Optimized coupling OD for maximum joint strength and downhole clearance

- Each weight optimized for maximum performance

AM-HBC

3 ½” TO 13 3/8”

- Successfully tested under ISO 13679:2002 CAL-IV and operator test protocols

- Product line qualification testing performed on broad size, weight and grade range

- Field proven design

- Suitable for use in wide range of applications

- Robust design

- Easy running

Metal-to-Metal Seal

- Conical seal provides high performing gas tight seal

- Seal geometry provides excellent anti-galling properties

Torque Shoulder

- Negative angle torque shoulder to enhance sealing

- Ensures precise make up position control

- Provides compression resistance in combination with the threads

Thread profile

- Run out thread provides maximum pipe body area for tension and compression

- Hooked threads lock the joint together for maximum tension loads and preventing jump out

- Steep stab flank angle and torque shoulder provide compression and bending resistance

- Thread form design provides excellent anti-galling properties

Other features

- Optimized coupling OD for maximum joint strength and downhole clearance

- High compression option

AM-C7S

4 ½” TO 13 3/8”

- Based on API Buttress design

- Coupling torque shoulder for increased torsional strength

- Designed for any application for API Buttress where greater torsional strength is required

- AM-C7S Couplings may be assembled with standard BTC pin*

- AM-C7S Pins may be assembled with standard BTC coupling

- BTC based thread design for easier operations

- Same ease of running as API BTC

*Torsional strength may be reduced during using the standard BTC pin

Torque Shoulder

- Provides enhanced torsional strength

- Allows controlled make up position for lower stresses

- Make up connections to specified torque values

- Better compression resistance than API BTC

- High yield torque value

Thread profile

- Standard API BTC thread form on both pin and coupling

- BTC thread seal

- Pressure and tension performance properties are same as BTC

AM-TS

4 ½” to 9 5/8”

- Extensive field usage Metal-to-Metal seal

- Smooth bore for better fluid flow

- Modified BTC thread form

- Gap between the box root and the pin crest for the excess of thread compound

Metal-to-Metal Seal

- Galling resistant seal

- Better sealability than API connections

- Suitable for higher temperatures than API connections

Torque Shoulder

- Enhances the sealing

- Enhanced compression resistance

- Provides positive stop during make up

Thread profile

- Modified buttress thread profile reduces galling

- Additional thread clearance allows for excess thread compound

For further information please contact us:

jubail.tubularproducts@arcelormittal.com